Traditional and innovative from raw to finished part

Welcome to our mechanical manufacturing department - Where the raw part becomes the finished part! Here, craftsmanship, state-of-the-art technology, and precision work combine to ensure the highest quality and process reliability.

Our manufacturing facilities, which are always at the cutting edge of technology, allow us to offer both standard processes such as turning and milling as well as specialized machining technologies such as friction stir welding for our customers.

Our work does not end with mechanical machining. Through our machinery, which also includes the latest washing facilities, we ensure that every product meets the requirements of our customers and also fulfills the highest residual dirt requirements.

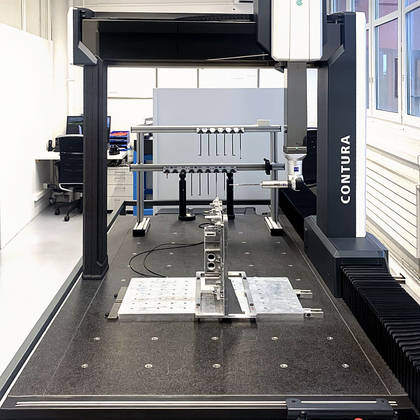

Our priority is on quality and reliability. We use state-of-the-art technologies, including individually designed facilities for differential pressure tests, to ensure flawless quality assurance of the parts. In addition, we offer laser markings for tracking the components.

In the final step, the precise assembly of the parts is carried out by our specialists at specially set up assembly stations. This final stage in the production process ensures that our customers receive products that exactly meet their specifications and requirements.

Our pursuit of excellence in every process step is expressed in an impressive combination of tradition and innovation. Convince yourself of our expertise and rely on quality that sets standards in the aluminum die casting industry. Contact our technical sales team for a non-binding consultation about our services!